INFRARED THERMOGRAPHY

INFRARED THERMOGRAPHY

Infrared Thermography Surveys - You’ve probably heard about this high-tech tool used to spot problems in electrical systems and equipment. Sir William Herschel discovered infrared radiation in 1800. Herschel termed this as ‘invisible radiation calorific rays'. Today we know it as INFRARED.

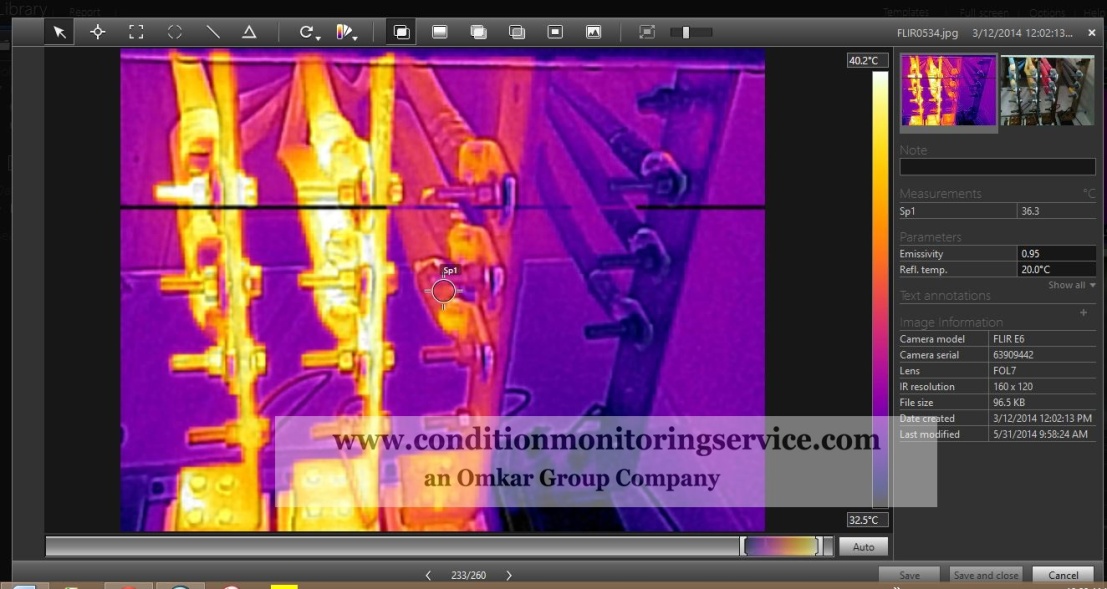

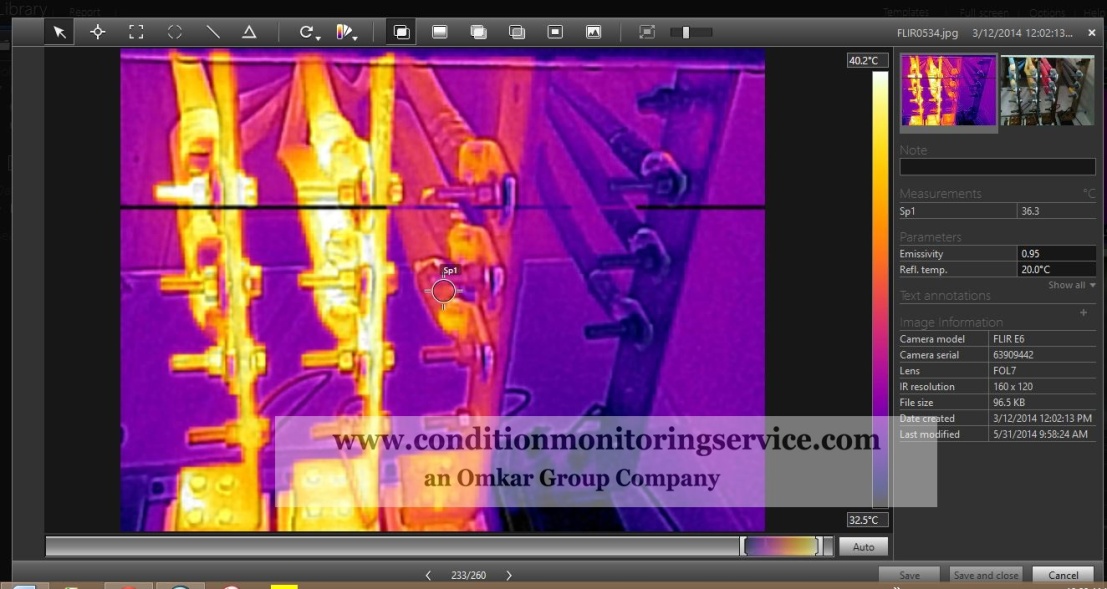

Essentially, the camera is detecting the energy levels from one surface and comparing that level with another surface. These energy levels show themselves as invisible light waves that are part of the electromagnetic spectrum known as infrared.

Infrared thermography utilizes a Thermal Imaging Camera which views a large area at a time, senses infrared emissions, and converts the emissions into a visual display. Large quantities of equipment are scanned while in operation, so production need not be interrupted. Trouble spots can be pinpointed quickly, saving labor and cost and targeting plant maintenance resources where they are needed.

Some studies have reported as much as a Four – to – One return for money spent on infrared inspection as a result of identifying potential component failure & preventing the much greater costs associated with manufacturing, downtime, production losses, power outages, fires and catastrophic failures.

Thermography of

Infrared Thermography Surveys - You’ve probably heard about this high-tech tool used to spot problems in electrical systems and equipment. Sir William Herschel discovered infrared radiation in 1800. Herschel termed this as ‘invisible radiation calorific rays'. Today we know it as INFRARED.

Essentially, the camera is detecting the energy levels from one surface and comparing that level with another surface. These energy levels show themselves as invisible light waves that are part of the electromagnetic spectrum known as infrared.

Infrared thermography utilizes a Thermal Imaging Camera which views a large area at a time, senses infrared emissions, and converts the emissions into a visual display. Large quantities of equipment are scanned while in operation, so production need not be interrupted. Trouble spots can be pinpointed quickly, saving labor and cost and targeting plant maintenance resources where they are needed.

Some studies have reported as much as a Four – to – One return for money spent on infrared inspection as a result of identifying potential component failure & preventing the much greater costs associated with manufacturing, downtime, production losses, power outages, fires and catastrophic failures.

Thermography of

- Electrical Systems: IR inspection is very surprisingly useful tool for finding anomalies in electrical systems. It can detect Unbalance Load, Odd Harmonics, Overload, Insulation Failure, Loose Connections, Wiring Mistakes, Faulty Breakers, Component Failure in following electrical systems.

- Electrical Panels – Switch Board

- Transformers

- Electric Sub-stations & Switch Yards

- Overhead Electricity Distribution System

- Battery Banks

- Capacitor Banks

- Electromechanical Systems: IR inspection is very useful tool for finding anomalies in electrical systems. It can detect bad cooling due to reduced air-flow, Winding Overloading, Bad Alignment, Faulty Bearings and overheated core etc.

- Motors

- Power Generators

- Brush Gear Assembly

- Mechanical Systems: IR inspection along with Vibration Analysis or Ultrasound Analysis is a complete tool for carrying out predictive maintenance of below mentioned machines/systems. Few of the major anomalies include rubbing of parts, overheating, jammed parts etc. In compressor, the compressor head temperature is major issue. It is always easy to inspect condition of number of bearings on kilometer long conveyers with the help of IR Thermography.

- Gear Box

- Bearings

- Compressors & Intercoolers

- Pumps

- Engines

- HVAC Plant

- Refrigeration Plant

- Drive Belts

- Conveyers Bearings

- Couplings

- Process installations: Here the major issues are overheating and insulation failure in these installations. Thermography is the only tool for condition monitoring of these installations. One can check the level of slurry residue in large storage tank, the heating of paper material over the rollers throughout the width in paper machinery, Leakages of steam & gas from transmitting systems, Clogged or Open Steam Trap, etc. with the help of IR thermography.

- Steam Traps, Steam Piping, Valves, Joints

- Refractory- Kilns

- Heat Exchangers

- Storage Tanks & Vessels

- Furnaces/ Ovens

- Boilers & Reactors

- Plastic Molding Machines

- Paper Mill Machinery

- Metal Industry machinery

- Underground Steam Pipe Leakages

- Condensers

- Building/ Concrete Structures: IR Thermography is the most important tool to check water proofing of roof/ terrace of buildings and rain water seepages through walls. It is also, useful tool for detecting the losses of cold/ heat from rooms/ houses. One can easily detect the moisture intrusion behind the POP paneling inside houses, with the help of thermography.

- Rain Water Leakage from Roof/ Terrace

- AC Air leakage from Room

- Heat Leakage

- Water Seepages from Walls

- Moisture Intrusion in POP paneling